Richlite

Find out how paper is being used to make sturdy, sustainable and water-resistant furniture.

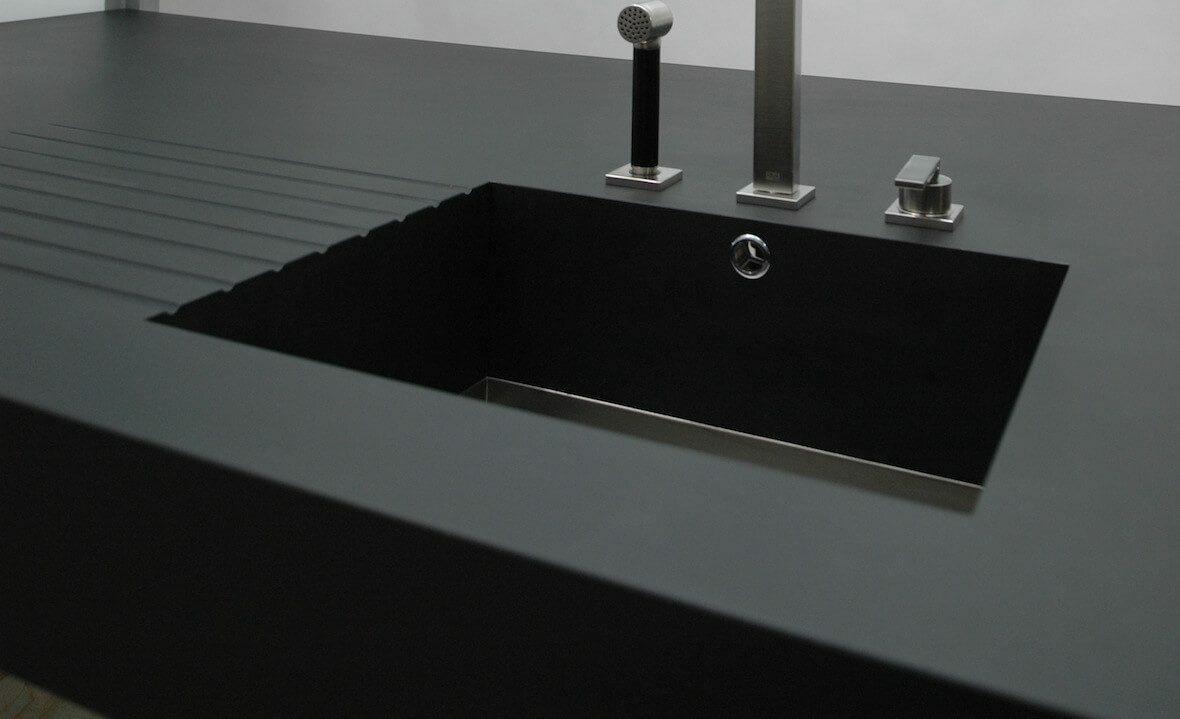

Even though the material was developed back in the 1940s, Richlite only started making its way into the commercial world in recent years. It wasn’t until the skateboarding industry discovered that this unique and sustainable material created from paper made perfect ramps, because it didn’t wear and was resistant to water, that other industries started to take notice. Now, you can find Richlite in everything from chairs and table tops to guitars. It's even found its way into exterior cladding, aerospace and automotive industries.

Paper isn’t the first thing that comes to mind when we need a luxurious, water-resistant and durable material, but the magic lies in the production process. Handmade from multiple layers of custom craft paper, the 65% FSC® certified or recycled paper and 35% resin mixture gives the final product its high impact resistance and strength. Richlite works like a dense hardwood and can be easily milled, sanded, routed and joined, while being heat, fire and water resistant, with low moisture absorption.

The process is simple, yet intricate when the paper gets saturated with resin and laid up by hand. The alternation of the paper’s direction is crucial to make it strong and stable. Pressing it under even heat and pressure melts the resin and bonds the sheets together. Thicknesses ranging from 6-75mm can be produced, which only adds to the versatility of Richlite.

We love the option of natural, leather or satin finishes - perfect for on-trend restaurant and bars seeking materials with the ability to withstand heavy use. It's also naturally antimicrobial, and similar to wood or leather, the colours develop a natural patina as they age, becoming darker, warmer and more dramatic over time. And if any scratches or patina bother you, it's easy to sand away and reseal, but the aged leather appeal definitely has its charm.